Punch Press / Stamping / Laser Cutting

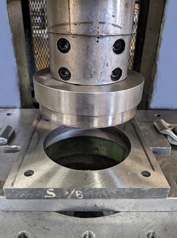

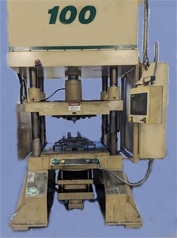

Many customers are requesting more than just a spun part, they want to get a s close as possible to a finished part. Holes and increasingly more complex hole patterns are one of most frequents for forming beyond spinning, Ace Metal Spinning has access to wide variety of kick presses, mechanical punch presses, stamping presses, and sheet lasers to provide a more complete part. This range of equipment helps supply difficult hole patterns in small or large quantities. human actuated kick presses are great for small diameter holes on the flat surface of light gauge parts.

Finally, Ace Metal Spinning uses CNC controlled turret punches and sheet lasers to create complicated patterns for regular and counter sunk holes on the flat surfaces of parts up to 44” in diameter. This unique capability is very useful on large commercial light fixtures.